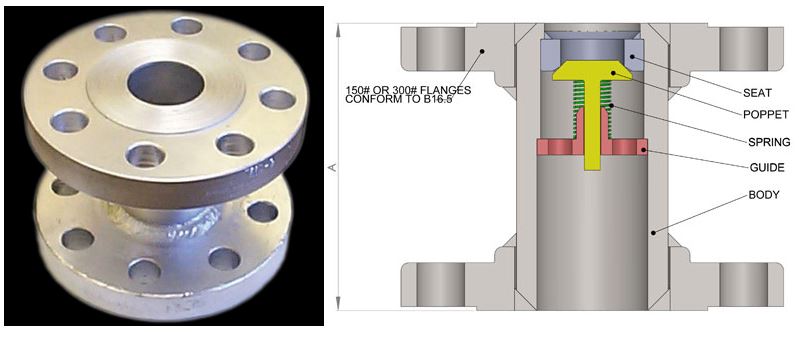

Model 230 MGM Flanged Back Pressure Check Valves

Application Overview

MGM Series 230 Back Pressure Check Valves are designed to allow flow in one direction only. They are made completely of carbon steel and/or stainless steel, not castings for added durability. The metal to metal seating allows slight leakage in the closed position.

The 230 Model MGM Back Pressure Check Valves are designed for installation in lines that flow into pressure tanks. They should be in inflowing lines when outward flow is never required. Model 230 MGM Back Pressure Check Valves can be mounted in any orientation. Each valve will have the proper flow direction indicated by an arrow stenciled in the body.

As with all MGM Back Pressure Check Valves, do not reduce outlet pipe size. Back Pressure Check Valves should be installed as close as possible to the container, with the poppet pointed inwardly toward the container.

Valve Features

- Designed to fit between American Standard steel pipe flanges. Ring Groove flanges can be furnished if required.

- A350 LF2 forged carbon steel flanges available in 150# or 300# ratings.

- Generous flow channels provide low pressure drops.

- Heavy duty all steel construction will withstand extremely tough conditions.

- Complete 304 or 316 stainless steel construction available for use in corrosive or extreme environments.

- UNDERWRITERS LABORATORIES INC. listed for propane, butane, and anhydrous ammonia.

- CRN # OC13500.5C

- Other valve sizes may be available. Contact MGM for alternate sizes.

Materials

- Body – Carbon Steel

- Poppet – Stainless Steel

- Guide – Carbon Steel

- Spring – Stainless Steel

Sizes & Dimensions

| Series | Dimensions | ||||

| A | |||||

| 230:I 2″ | 4.5 | ||||

| 230:K 3″ | 5.25 | ||||

| 230:M 4″ | 6.0 | ||||

| 230:P 6″ | 8.63 | ||||

| 230:Q 8″ | 10.0 | ||||

| 230:R 10″ | 13.13 | ||||

All Size Values are in Inches.