MGM Valves

MGM Valves

Hemco Industries manufactures the equipment needed to keep your projects running smoothly – and safely. In addition to fall protection, gangway systems, loading racks and loading arms, Hemco Industries also supplies a full line of MGM Flow Valves. Our line includes Threaded Excess Flow Valves, Back Pressure Valves, Flanged Flow Valves, Wafer Excess/Back Pressure Valves and much more. All of MGM’s Valves are Threaded and Flanged Valves are made completely of carbon and stainless steel.

The MGM Threaded Excess Flow Check Valves are designed for use where threaded connections are required. They are made completely of carbon and stainless steel. Bodies are machined from bar stock, not combined in sections, for added durability. The MGM Threaded Excess Flow Check Valve have male pipe threads on top (inlet) and bottom ends and female pipe threads in the lower end. The Threaded Series includes valves that can be mounted in any orientation with negligible effect on flow rate, and that are equipped with an orifice in the check mechanism to allow for pressure equalization and will reopen automatically after repairs are made.

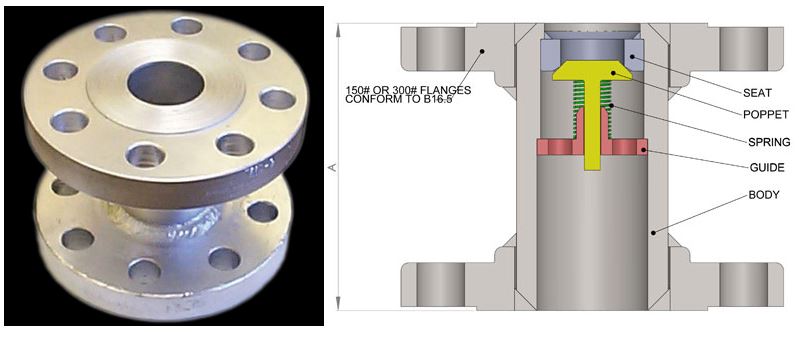

The Flanged Excess Flow Check Valves are designed for use where flanged connections are required. They are made completely of carbon and/or stainless steel not castings for added durability. The Flanged Check Valves are double flanged and are equipped with either 150# or 300# raised face, forged flanges. Standard gaskets should be used on each end. This series of valves can be installed in any orientation with negligible effect on flow rate. Each valve has the proper flow direction indicated by an arrow stamped into the body.

Back Pressure Check Valves are designed threaded and flanged and built to allow flow in one direction only. The check mechanism is held in the closed position by a spring. This stops flow in the reverse direction. They are made completely of carbon steel and/or stainless steel not castings, for added durability. When pressure from flow in the permitted direction overcomes the force of the spring, the check mechanism opens. When this flow stops or reverses, the check closes. The metal to metal seal allows slight leakage after closure. These valves are recommended for use in all inflowing lines. They may be used in any position. Back Pressure Check Valves are designed for installation in lines that flow into pressure tanks. They should be in inflowing lines when outward flow is never required. All MGM Back Pressure Check Valves, do not reduce outlet pipe size. Back Pressure Check Valves should be installed as close as possible to the container, with the poppet pointed inwardly toward the container.

The Wafer Excess Flow Check Valves are single flanged, wafer style valves with various designs that can fit inside Schedule 80 pipe or 160 tank nozzle pipe. The valve flange will fit inside the bolt pattern of 150# or 300# flanges. Standard gaskets should be used on both sides of the valve. The Wafer Flow Check Valves can be mounted in any orientation with negligible effect on flow rate. Each valve will have the proper flow direction indicated by an arrow stenciled on the flange. The Wafer Back Pressure Check Valves are designed to allow flow in one direction only. They are made completely of carbon and stainless steel and are machined from bar stock, not castings, for added durability. The metal to metal seating allows slight leakage in the closed position.

The MGM Back Pressure Check Valves is designed for installation with lines that flow into pressure tanks. They should be used in inflowing lines when outward flow is never required. This valve can be mounted in any position. Each valve will have the proper flow direction indicated by an arrow stenciled in the body.

All MGM flow check valves are equipped with an orifice in the check mechanism to allow for pressure equalization and will reopen automatically after repairs are made.

Get a FREE quote on the Hemco Excess Flow Check Valve, just fill out the Request A Quote form and a product specialist will contact you shortly. You can always reach us by phone at 713-681-2426 or toll-free at 877-394-3626.

Hemco Industries manufactures the equipment needed to keep your projects running smoothly – and safely.