Fall Protection and Fall Prevention!

Every year safety continues to be one of the most important issues and topics discussed within the industrial industry. The industrial industry has seen over 110 million onsite accidents with the most common of those accidents and injuries pertaining directly to falls. Companies continue to implement the necessary measures to avoid falls but when measures are overlooked, or simply don’t work properly, and injuries occur this can cause employees to take a leave of absences from the workplace for an extended period, others may lose their job all together, and in the worst-case scenario fatalities may occur. These situations are not to be taken lightly, this hurts and heavily impacts employees and their families, this can also seriously impair the business involved. Hemco can provide all your railcar loading and unloading as well as tanker truck loading and unloading project needs.

Leader in Fall Protection. Gangways, Railcar Loading Platforms and Truck Loading Platforms.

Built for safety, engineered for a lifetime, fall protection you can count on!

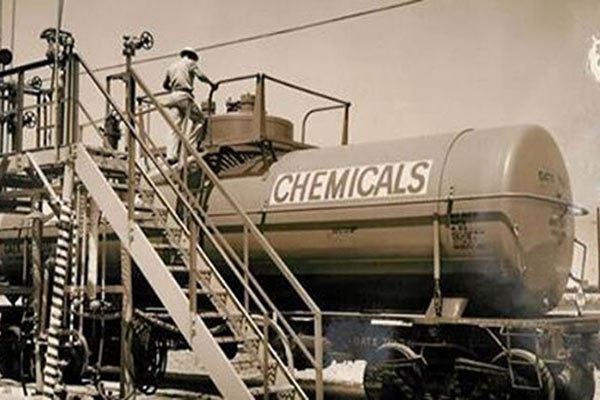

Since 1956 Hemco Industries has been a leading manufacturer of world-class gangways, railcar loading racks, tanker truck loading racks, and other fall protection products and safe access solutions that provide optimal safety for your operators. Hemco fall protection systems are designed to deliver easy access and provide personnel safety, our diverse product line can handle all of your bulk loading and unloading needs. At Hemco we not only have years of experience in manufacturing advanced safe access solutions built with quality designs, but we also take pride in being an Engineering firm that solves each customers problem.

Achievements

YEARS IN BUSINESS

CLIENTS SERVED

PROJECTS COMPLTED

GANGWAYS

The Hemco Titan Gangway and Self-Adjusting Stair Gangways are designed with the maneuverability required for safe and efficient modern day loading, unloading, and sampling operations.

LOADING PLATFORMS

Hemco truck and railcar loading racks and platforms are designed to withstand heavy loads and provide safe and efficient access in any situation that your operations require.

LOADING RAMPS

Hemco Loading Ramps provide a level walking surface for operators in difficult to reach areas. Manufactured with carbon steel our ramps include open bar grating, serrated for slip-resistant footing.

SAFETY GATES

Our steel framed Adjustable and Standard sized Safety Gates provide openings and access points with protection and easy accessibility for loading operations.

Fall protection built to last! We use carbon steel in our designs, and for good reason.

Hemco has products delivered to customers in the mid-1960’s that are still in use today. This type of product longevity and durability would not be possible using aluminum. Due to the critical safety nature of our product applications, combined with the industrial weight and moment loads that our products experience, carbon steel is clearly the superior choice.

Today, Hemco continues to provide access solutions to such companies as Exxon/Mobil, Conoco, DOW Chemical, DuPont, Union Pacific, and more.

We offer both standard products and custom fabrication for the most complex bulk loading applications. Our company’s experienced product specialists and engineering staff are ready to provide safe solutions, competitive pricing, and superior post-sales service for any application you may have.